The best way to save energy in the industry – Electrical monitoring

Saving energy represents the way and the idea that it is possible to reduce the load of energy and the end of the load or to reduce the load as can be expected in a reasonable way and the goal the greatest of which is not to destroy the comfort of life. With the right Discount Power saving measures, businesses can save a large number of dollars spent on the wasted effort, and organizations can meet their energy needs and can save similar energy costs. For example, turning off critical equipment when not in use and replacing old motors with less powerful and more efficient ones is an amazing way to cut costs. There are many companies that use old machines, which will be replaced. Let’s assume that a motor with an efficiency of 83% has an electrical expense at any time of about $3923 when replaced by a motor with an efficiency of 87.5%, which will consume electrical energy of a value of $3734 in savings per year of $ 189 can. Will understand

- Energy system:

An energy plan is a report or guideline that includes measures and actions to be taken to save energy. There are a few principles by which power plans are created.

For example, ISO 50001, a standard designed for energy management purposes, can:

Development of energy strategy for efficient use of energy. Set goals and objectives for the plan. Information analysis for better understanding and decision-making in energy use. Results analysis. Review the policy

- Power Instructions:

A normal power balance helps to determine the power issue due to different gears, as well as the area where the majority of the impact is taken and what steps can be taken to reduce the impact of use without having an impact on nature.

Power instructions include the following improvements:

Step-by-step analysis: This includes analyzing the large and small loads of the general area, the type of work being done there, the number of employees, movements and schedules, etc. The results of these tests can be like replacing the old CFL lamp with a motor and reducing the number of lights per light presence, etc. Clear review: It includes the collection of information, the integration of costs, the suffering due to equipment, the replacement of old hardware with another one and its plan for the period of service and the significant progress that the company should take to save energy, which may include training its employees. -protecting progress and giving incentives to representatives who demonstrate responsibility towards them.

- Eco-Friendly Energy:

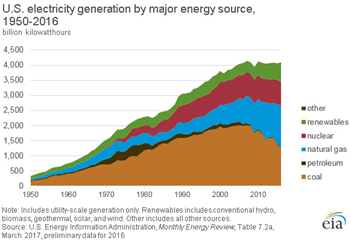

Eco-friendly energy use is becoming more common these days, as the source of energy is free and unnecessary from fossil fuels. Environmentally friendly energy includes the use of wind energy, solar energy, biomass energy, etc. Stacking power is provided by a combination of non-power electronics components. The use of sustainable energy in the modern industry can also be a source of cost reduction and interest in the organization of the project. For example: in today’s scale, introducing solar-based load carriers and powering them can help reduce the burden of the Age of Force. Environmental energy depends on sunlight and wind

- Good lighting:

Electric motor:

Using an electronic counterweight in the tube light instead of the old electromagnet effect can also reduce power consumption. Electronic statistics

By Dennis Brown – Own work, CC BY-SA 3.0, Attribution

These portable lights:

Replacing fluorescent and incandescent lights with lower wattage is a good way to manage energy savings. For example: by replacing a 40-watt, 500-lumen incandescent bulb with a 7-watt bulb that gives the same lumens (beauty), then it is possible to save about 33 watts (40 short 7s). 7-watt control lamp.